The Role of Industrial Aluminum Profiles in Modern Manufacturing

Often hidden behind the scenes, industrial aluminum profiles are the building blocks of many industries — from automation systems and cleanrooms to transportation, solar racking, and custom machinery. Their adaptability and performance have made them a staple in 21st-century manufacturing.

1. Why Aluminum?

Aluminum offers an ideal combination of properties:

-

Lightweight but strong — easier handling, faster installation

-

Corrosion-resistant — suitable for outdoor and humid environments

-

Excellent machinability — can be drilled, cut, and assembled with ease

Our aluminum alloys (mainly 6063-T5/T6 and 6061) meet both mechanical and surface finish requirements for high-end applications.

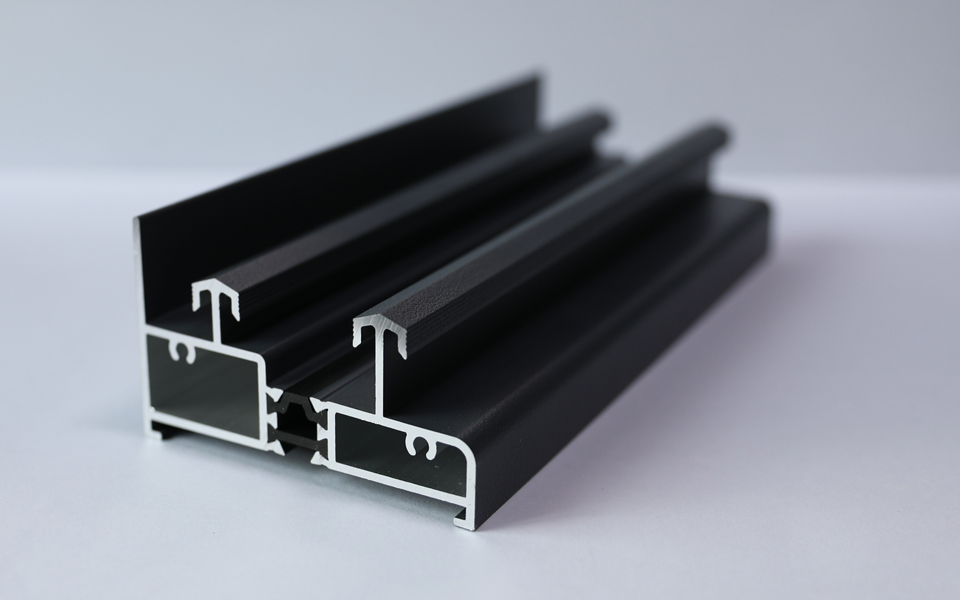

2. Flexible Design for Complex Needs

Our extrusion capabilities allow for:

-

Precise custom profiles with tight tolerances

-

Multiple cavity designs for added strength

-

T-slots, channels, and integrated mounting systems

Customers can choose from:

-

Modular aluminum framing

-

Enclosure and rack systems

-

Machine guarding and conveyor systems

3. Surface Finishing and Treatment

We offer various surface treatments to meet your aesthetic and functional needs:

-

Anodizing for wear and corrosion resistance

-

Powder coating in a wide range of colors

-

Electrophoresis and PVDF for architectural-grade finishes

All finishes comply with international quality standards for adhesion, thickness, and gloss.

4. Industries Served

We proudly serve clients across sectors including:

-

Manufacturing and automation

-

Construction and facade engineering

-

Electronics and cleanrooms

-

Transportation, solar energy, and more

5. Custom Processing and Assembly

Need pre-drilled holes, notches, welding, or cut-to-length profiles? We provide:

-

CNC machining

-

Pre-assembly services

-

Kit packaging for easy installation at your site

Our expert engineering team works closely with customers to ensure seamless integration into their systems.